Environmental Benefits

Waterjet cutting inherently is an environmentally friendly process. Unlike traditional mechanical cutting systems, waterjet cutting requires no cooling or lubricating oils. This means there are no chemically contaminated chips to dispose of. Unlike thermal processes such as plasma or laser, waterjet generates no noxious fumes during the cutting process. This is why it is classed as a green technology.

At Westcountry Waterjet we recycle all the spent abrasive and waste material. The garnet abrasive is inert and is non-toxic, due to the fact very little metal is actually removed in the cutting process very little actual metal goes in to waste. This keeps the environmental impact relatively low.

Paperless

Paper product manufacturing contributes significantly to deforestation and man-made climate change, and produces greenhouse gases. paper manufacturing is the third largest user of fossil fuels worldwide, couple that with the fact that most paper still ends up in landfill.

Printing inks and toners are very expensive and use environment-damaging volatile organic compounds, heavy metals and non-renewable oils.

Here at Westcountry Waterjet we pride ourselves on being Environmentally Friendly and as such operate a near Paperless office, all invoices, purchases etc will be e-mailed wherever possible.

Case Studies

-

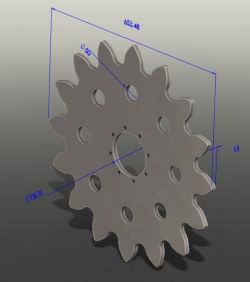

Bespoke Sprockets from...

"Westcountry Waterjet has recently profiled some bespoke sprockets from Hardox for a Sorcerer rotational...

View -

Copper Gaskets

Mr Price needed a copper gasket/spacer for a project he was working on, having no way...

View

Copyright ©2024 Westcountry Waterjet, Company No. 8945226, VAT No.186217983

Site design by Somerset Design