Services

Westcountry waterjet (WCWJ) have the capability to cut most materials from Plastic to Granite, from 0.1mm thin to 250mm thick, as long as its flat we can probably cut it!

Quotes

Here at WCWJ we know the Importance of a supplier who you can rely on in all aspects of the relationship, when it comes to quotes we will usually return a quote within an hour, with all information and prices laid out clearly and concisely you can be sure there will be no hidden extras added after the job is complete.

Applications

Machining / Engineering

The versatility of waterjet cutting means that it can rough out blanks for machining or it can cut high quality accurate finished parts which traditionally would have been milled from a single billet and because of the cold process of waterjet cutting there are no hardened areas or faces which would be more costly to machine.

Construction / Architectural

Granite and marble worktops, ceramic floor and wall tiles can be cut and shaped to customers spec many of which could not be done using traditional methods.

Aerospace / Marine

Due to the high material prices involved in these industries, the big advantage of waterjet is that parts can be nested very close together and can also share common cut lines.

Artistic / Signage

Waterjet cutting is ideal for cutting signage as its cuts so many different materials from wood and plastic to highly polished materials such as stainless steel and aluminium.

Case Studies

-

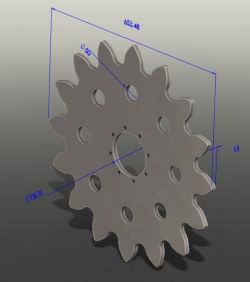

Bespoke Sprockets from...

"Westcountry Waterjet has recently profiled some bespoke sprockets from Hardox for a Sorcerer rotational...

View -

Copper Gaskets

Mr Price needed a copper gasket/spacer for a project he was working on, having no way...

View

Copyright ©2024 Westcountry Waterjet, Company No. 8945226, VAT No.186217983

Site design by Somerset Design